10 Smart Reasons

-

Handles a wide variety of fluids with high solids content: No close fitting or rotating parts so liquid with high solids content and/or size can be easily pumped.

-

Self Priming: The Neoflux pump design allows for high suction lift even at dry start-up and with heavier fluids.

-

Ability to run dry: No close fittings or sliding parts are at risk–the pump can run dry without damage.

-

Variable flow rate and discharge pressure: Neoflux pumps will run at any setting within their operating range simply by adjusting the air inlet pressure and system conditions. Are capable of pumping as slow as one gallon per minute. One pump can fit a broad spectrum of applications.

-

Portable/Simple Installation: Neoflux pumps transport easily to the application site. Simply connect your air supply line and liquid lines; the pump is ready to perform. There are no complex controls to install and operate.

-

Dead Head: A situation that occurs when the pump's discharge is closed either due to a blockage in the line or an inadvertently closed valve. At this point, the pump will go to its maximum shut-off head; the fluid will be re-circulated within the pump resulting in overheating and possible damage. In AODDP, because the discharge pressure can never exceed air inlet pressure, the discharge line can be closed with no damage or wear. The pump will simply slow down and stop.

-

Shear Sensitive: The gentle nature and minimal parts contact with the liquid makes Neoflux pumps an excellent choice for shear sensitive fluids.

-

Explosion Proof: AODD pumps are operated by compressed air, therefore, they are intrinsically safe.

-

Submersible: If external components are compatible – Neoflux pumps can be submerged in the liquid by simply running the exhaust line above the liquid level.

-

Pumping efficiency remains constant: There are no impellers, rotors, gears, or pistons, which wear over time and lead to the gradual decline in performance/flow rate.

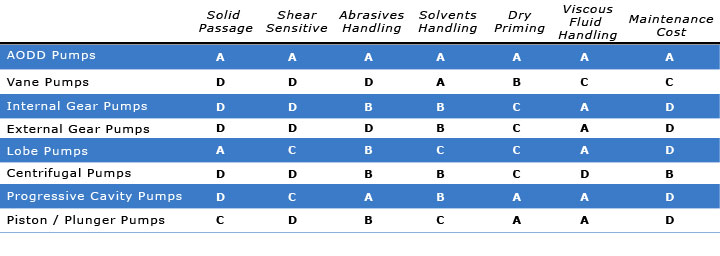

Comparison Chart of AODDP with Rotary & Centrifugal Pumps

Neoflux pumps are self-priming, can handle viscous and abrasive products, can run dry without damage, and are capable of passing compressible solids. These pumps do not employ costly motors, variable speed drives, by-pass plumbing or mechanical trip rods. Please see the matrix below for a comparison of the AODDP versus Rotary and Centrifugal pumps.

A = Excellent B = Good C = Fair D = Poor

A = Excellent B = Good C = Fair D = Poor

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|