The Neo-Mag Advantages

GFRPP / PVDF Auto Injection Molded Parts

All Neo-Mag Plastic components are Injection (Compression) molded at high temperatures & Pressures for even distribution of reinforced glass fibers, smooth hydraulic passages for higher efficiency & higher structural strength.

DRY-RUN Capability for hours through HEAT DISPERSING TECHNOLOGY

The revolutionized bushing design with Cooling channel circulation on surfaces of the bearing contributes to rapid heat dissipation. The circulation leakage of the sealless pump is fully utilized to reinforce convectional heat transfer to thermally balance internal temperatures and prevent damage even under dry running conditions.

Neo-Mag incorporates an additional fluid flow path around the bushing. This additional path allows the process fluid, or air, to cool the bushing of the impeller through the internal spiral cooling channel. This unique feature prevents the heat build-up that so often damages or completely disables the shaft bushing.

The Neo-Mag Pumps can run dry without damage when equipped with a chemical grade Carbon Bearing Kit in optimum operating conditions. This helps protect the pump from operator errors and system upsets.

The Neo-Mag design has a low pressure zone at pump drive. This ensures that a small amount of pumped media circulates around and through the Magnetic drive. The differential pressure draws media up the inside wall of the zone. The media is returned through the centre of the inner magnet. Every second spline in the drive shaft is used to channel the liquid back down again, cooling the upper bushing at the same time.

The pumped liquid acts as a cooling medium to dissipate the heat generated from eddy currents as the magnets pass around the containment shell.

Bushing Protection

An unavoidable by-product of a magnetic coupling is heat, which increases the risk of overheating and damaging the bushing. The risk has been reduced considerably by achieving such a high degree of efficiency. This in itself minimizes the heat generated around the Magnetic Capsule.

* The bearing is always submersed in the pumped media.

Easy Set Outer Drive

Measurement-free outer drive ensures optimum magnet alignment and easy motor installation. Allows optional vertical operation when used with IEC motors.

Back Pull-Out Design

Back Pull-Out construction allows Neo-Mag internal parts to be checked or replaced without disturbing piping. Components such as Bushing and Thrust Washers can easily be replaced individually.

Volute Casing

Neo-Mag Pump incorporates Volute Casing for better hydraulic efficiency & Performance. Volute design builds higher head compared to traditional Circular Casing. Due to its Volute Design, the casing will steer & evenly distribute water power towards impeller’s periphery.

Multiple Impeller Diameters

Allows hydraulic requirements to be precisely met. Two-piece impeller design allows impeller to be changed without having to replace inner drive.

G2.5 Balancing for Vibration Free Operation

A impeller balanced to G2.5 Grade will vibrate at 2.5mm/sec velocity if freely suspended while rotating at service speed. (2.5mm = 0.10 IPS).Achieving the above balancing tolerance will gives a vibration free operation.

High Performance Magnetic Capsule

Neo-Mag pumps feature high-powered, rare earth magnetic couplings which allow the transmission of maximum horsepower. All Magnetic Capsules are precisely machined to create a balance magnetic field. We utilize magnetic field analysis to calculate magnetic torque and maximize magnet utilization to ensure sufficient torque margin to prevent decoupling.

Torque (T) is a function of Horsepower (HP) and Operational Speed (RPM)

T = HP X 5250

RPM

Note:The Torque required by a pump application must not exceed the Torque limit of the pump shaft. High viscosity/Low speed applications produce high torque requirements.

Corrosion-Proofing the Magnetic Capsule

The magnets themselves are by nature highly susceptible to corrosion. Since the environment around a Neo-Mag is expected to be hostile, the magnets are encapsulated in Unfilled Polypropylene. This is unique to Neo-Mag Pump and gives it an unparalleled long lifetime.

Small, lightweight and perfectly concentric magnet capsules optimize pump efficiency.

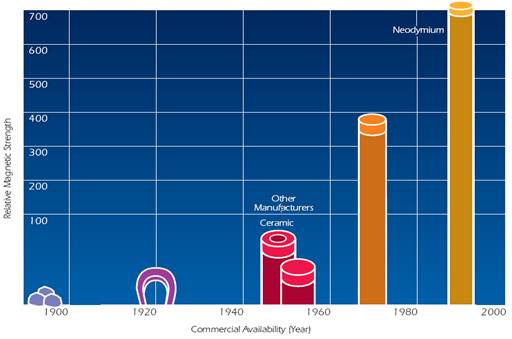

Powerful Rear-Earth Neodymium Magnetic Coupling

Neodymium rare-earth magnets increase pump operating life. Incredible magnetic power handles high specific gravity with no impeller trimming. Smaller magnet size allows a lighter weight rotating impeller while increasing performance. Neo-Mag rotating parts are 1/7th the weight of conventional ceramic magnetic pumps.

No Slippage, No Induction Currents = Zero Eddy Current Loss

The rock solid essence of technological advancement is superior in precision, performance and reliability to other pumps on the market.

With a Neoflux’s Neo-Mag Pump, losses are as low as 3 - 6 % in motors from 2hp to 5hp. In almost all situations, Neo-Mag can continue to deliver the same performance without derating the motor.

Neo-Mag’s non-metallic containment shell cover eliminates eddy currents and preventsany sparks from occurring in the event ofdrive magnet contact. In case of metallic shells, these losses could range from 10-15% of magnetic drive ratings.

Zero Eddy Current Losses - Power losses due to electrical currents produced by the rotating lines of magnetic flux cutting through a stationary conductor. These power losses translate into heat which is transferred to the pumping media.

The permanent magnet coupling in the Neo-Mag drive centrifugal pump causes neither slippage nor induction currents during rotation. If excessive torque is applied, the magnets will de-couple. The magnets will not re-couple unless the pump is stopped. There is no energy loss in a permanent coupling unless an electrically conductive containment is placed between the outer and inner magnets. If an electrically conductive material is used for the containment, eddy-currents will be generated which will cause some energy loss. Neo-Mag drives use non-conductive materials and therefore have no or only small eddy current losses.

All Neo-Mag Magnetic Capsules are precisely machined & balanced to achieve a balanced magnetic field to create the rotation of the fluid impeller.

Integrated CAD / CAE System Design

Using fully Computer Aided Design & Magnetic Flux analysis to assist product development, modern design concepts help Neoflux products reach the highest technical levels in industry.

Compact Footprint & Closed Coupled Design

Neo-Mag pumps are Closed-Coupled & Light Weight in construction with Compact Footprints which minimizes your floor space requirement – SPACE SAVING INSTALLATION. Neo-Mag pump does not need to be aligned during installation which requires special skills& tools like other traditional base mount pump designs.

Design for Safety

We have weighted safety and reliability very highly. Neo-Mag is made of the same GFRPP or PVDF material as all other of its components in contact with the pumped media. And it is designed to withstand pressure and temperature conditions beyond those of the pump itself.

For example, a Neo-Mag is designed to withstand continuous operation at a maximum of 79°C. The magnets can tolerate a maximum temperature of 130°C.

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Features

- Lower energy consumption & operating cost over the long life cycle of the pump.

- An User Friendly & Maintenance Ease Design with minimal parts & no special tools.

- A hermetically sealed drive system for leak free pump operation

- Close-coupled design with Volute Casing.

- Injection (Compression) Molded GFPP or PVDF construction for excellent chemical & corrosion resistance

- No environmental contamination

- Replaceable shaft

- Closed Impeller for lower power requirements and higher efficiencies.

- Rear Earth Neodymium Iron Boron Magnets (NdFeB) for higher temperature resistance

- Unmatched Coupling Strength

- ISO 1940 G2.5 balancing

- Mounts to Nema and IEC motor frames

- Vertical Installation option with IEC Motor

- Mounts to motor without disassembly

- Back pullout design for ease of maintenance

- One-year warranty

- CE certified/ATEX available.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|