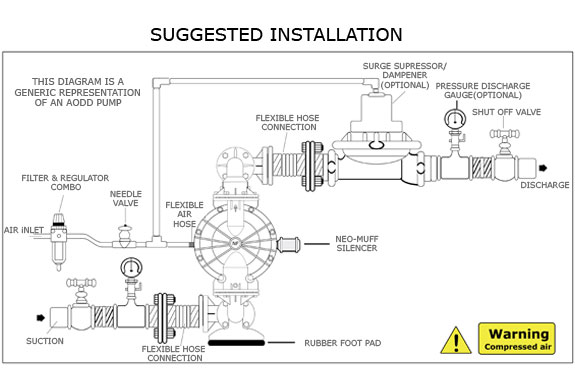

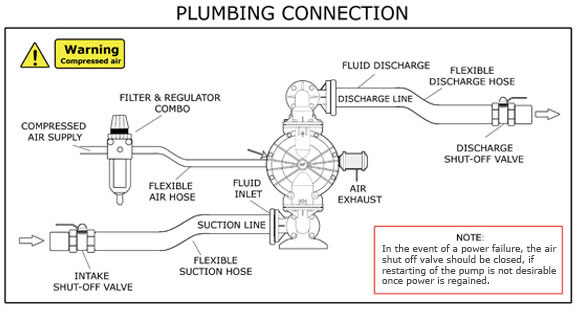

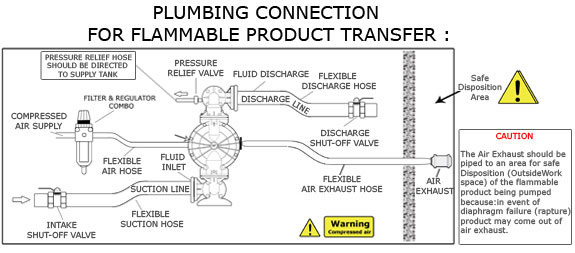

Plumbing System Design

When a pump is to be incorporated in a system, it is good practice to, as far as possible, minimise the length of the pipes/hoses and the number of fittings (tees, unions, bends, etc.) and restrictions. When designing the suction lines, particular care should be taken. Refer to pump model's EOM for detail plumbing information.

AODDP Pre-Installation Checklist

-

Verify pump model received against purchase order or spec sheet.

-

Remove shipping plugs.

-

Pumps that need to be submersed must have both wetted and non-wetted parts compatible with material being pumped.

-

Submersed pumps must have a hose attached to pump’s air exhaust to keep exhaust air piped above liquid level.

-

Pumps should be thoroughly flushed with water before installation.

-

Do not exceed 8.6 bar (125 psig) air supply pressure 50 psig on all Neoflux models. More the pressure, more the wear & Tear of the pump and Diaphragm. Ideal Air Pressure should be 4 to 5 bar.

-

Blow out air line for 10 to 20 seconds before attaching to pump to make sure all pipe line debris & moisture is clear.

-

Check the Discharge LPM to ensure optimum efficiency of the Pump.

Pump Commissioning

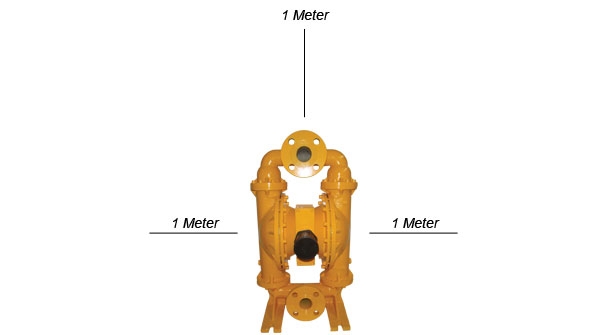

Install the pump to desired place in vertical position.

Figure: Minimum space requirement around the diaphragm pump

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|