|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

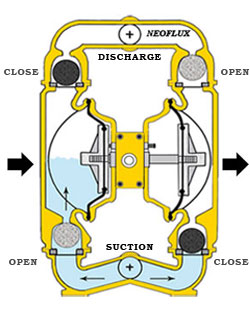

Diaphragm Pumps are common industrial pumps that use positive displacement to move liquids. These devices typically include a Two Diaphragms and Liquid Chambers, as well as suction and discharge check valves to prevent backflow. Pistons are coupled to the diaphragm.

Diaphragm pumps are highly reliable because they do not include internal parts that rub against each other. In fact, prolonged diaphragm life may be possible if the diaphragm pump is run dry to prime. Typically, wear on the diaphragm or flap is due to the corrosive properties of media fluids or gases and/or excessive air supply pressures.

Principle Of Operation

Stage - 1 Stage - 2 Stage - 3

Type

Self Priming, Positive Displacement, Reciprocating Air-Operated Double Diaphragm Pump. It is also known as AODD Pump.

Major Fractions

-

Wetted Components - Parts that come into contact with process fluid.

-

Air Distribution System - Air Chamber, Center Section, & Air Valve Assembly.

-

Elastomers - Diaphragm, Valve Balls, Valve Seats, O-rings & Gaskets.

Vital Fractions

-

The flexible diaphragms (shown in black here) are round disks attached at each end of the common shaft.

-

The PILOT SPOOL (located on top of the diaphragm shaft) is pushed back and forth whenever the Diaphragm Shaft reaches the end of its throw. The Pilot Spool allows air to move the Air Distribution Valve back and forth.

-

The AIR DISTRIBUTION SYSTEM controls air flow to the left or right air chamber, reversing on each stroke. This action causes the other side to draw product into the pump on a suction stroke.

-

The four BALL VALVES are free-floating and operated by pressure differences in the pumped liquid. In the pump shown, liquid flow is from the bottom to the top.